Metal curtain wall is a new type of architectural curtain wall. All of its properties, including excellent processing performance, color diversity and ensured safety, can be designed into various complex shapes, and can process various types of curved lines, gives architects a huge space to design and thus metal curtain wall gains rapid development.

1. Classification of metal curtain walls

Metal curtain walls are classified according to panel materials. They can be divided into color coated steel plates, aluminum veneers, Aluminium-Verbundplatten, aluminum honeycombs panels, anodized aluminum plates, titanium zinc plates, stainless steel plates, copper plates, und so weiter. According to different surface treatments of panels, metal curtain walls can be divided into mirror panels, mat panels, profiled panels and corrugated panels.

(1) Color-coated steel plate

Color coated steel plate is made of cold-rolled strip steel and galvanized strip steel (electro-galvanized and hot-galvanized) as substrates on a continuous unit. After surface pretreatment (degreasing and chemical treatment), the substrate is coated with one or multiple layers of liquid paint by roller coating, then baked and cooled. It has the advantages of beautiful appearance, bright colors, high strength, good corrosion resistance, convenient processing and molding, usw., and can also reduce the cost for users and reduce pollution.

Disadvantages of color-coated boards

- The maintenance cost is high. As the external painting and plastic spraying will peel off after a long time, which will affect the appearance, it is generally necessary to do maintenance every 2 Jahre.

- Poor thermal insulation and sound insulation performance. Allgemein, the performance of thermal insulation and sound insulation of color-coated movable houses is relatively weak. Improve of the thermal insulation and sound insulation effect will require thicker inter-layerand partition board, which will increase the cost.

- Weak resistance to wind and snow and pressure. Allgemein, the boneless color steel houses are weak in compressive strength, and generally only one floor is built. The C-shaped steel and I-shaped steel are used in skeleton mobile houses, which can greatly improve the compressive strength, but they are generally not recommended for the construction of permanent buildings.

- It rusts easily after a long time. When the coating is peeled off, as the inside is steel plate, it is easy to rust, thus affecting the use. Derzeit, the most widely used hot-dip galvanized base plate for building materials has a large capacity, but there is a lack of good base plates such as flat hot-dip galvanized steel coils without zinc flakes and zinc alloy coated steel coils.

(2) Aluminiumfurnier

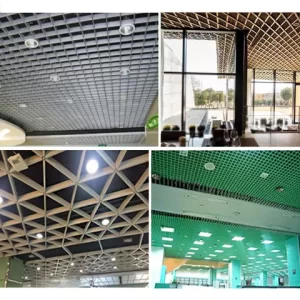

The aluminum veneer curtain wall is made of high-quality and high-strength aluminum alloy plates. Its common thickness is 1.5, 2.0, 2.5, Und 3.0 mm. Its structure is mainly composed of panels, reinforcing ribs and corner codes. The corner code can be directly bent and stamped from the panel, or the corner can be riveted on the small side of the panel. The reinforcing rib is connected with the electric welding screw at the back of the panel, making it a solid whole, which greatly enhances the strength and rigidity of the aluminum veneer curtain wall, and ensures the flatness and wind and earthquake resistance in long-term use. If sound insulation and thermal insulation are required, efficient materials can be installed on the inside of the aluminum plate.

Aluminum veneer curtain wall is suitable for the decoration of various building interior and exterior walls, lobby facades, column decorations, elevated corridors, pedestrian bridges, elevator edging, balcony decoration, advertising signs, indoor special-shaped ceilings, usw. It is also suitable for high-rise buildings such as building external walls, beams and columns, Balkone, canopy airports, stations, hospital conference halls, reception halls of opera houses and stadiums, usw.

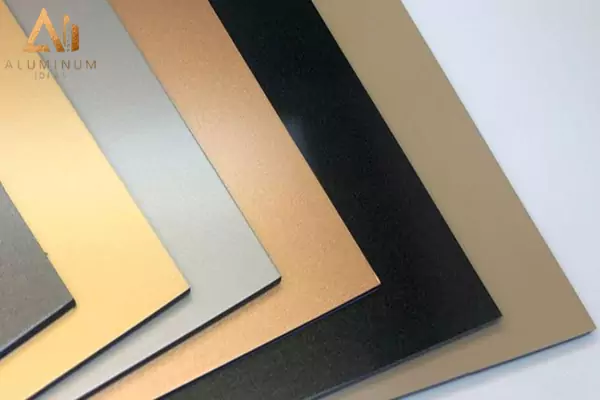

(3) Aluminium-Verbundplatte

The aluminum composite panel is composed of upper and lower layers of 0.5mm-thick aluminum plates, mit 2 ~ 5 mm thick polyethylene or rigid PVC foam plates sandwiched between them. The board surface is coated with fluorocarbon resin coating, which is a stable film layer with strong adhesion and durability and rich colors. The back of the board is coated with polyester paint to prevent potential corrosion. Aluminum composite panel is a common panel material when metal curtain wall appeared early.

The unique performance of aluminum composite board determines its wide application: it can be used for building exterior walls, curtain wall panels, renovation of old buildings, interior wall and ceiling decoration, advertising signs, display stands, purification and dust-proof projects.

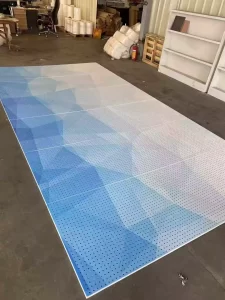

(4) Wabenplatte aus Aluminium

Wabenplatte aus Aluminium is a series of metal composite panel products developed by combining composite honeycomb panel technology in aviation industry. This product adopts “honeycomb sandwich” structure, das heißt, the high-strength alloy aluminum plate coated with decorative coating with excellent weather resistance is used as the surface and bottom plate, and compound with aluminum honeycomb core at high temperature and high pressure.

Without any reinforcement measures, the size of honeycomb aluminum plate can reach 1500*5000 mm, and it can keep excellent flatness. And it can bear high-strength pressure and shear force. It is not easy to deform, and can meet the requirements of wind pressure resistance of super high-rise buildings. In terms of size, Form, paint surface and color, it can also be tailored according to customers’ Bedürfnisse.

(5) Anodized aluminum plate

Anodized aluminum plate is made by placing the aluminum plate in the corresponding electrolyte as an anode, and conduct electrolysis under specific conditions with applied current. The aluminum plate in the anode is oxidized and a thin layer of aluminum oxide is formed on the surface. After anodizing, the hardness and wear resistance of aluminum plate are improved, and it has good heat resistance. The melting point of hard anodized film is as high as 2320K. The breakdown voltage of the oxide film is as high as 2000V, and it will not corrode in high-strength salt spray for several thousand hours. There are a lot of micro-pores in the thin oxide film, which can absorb all kinds of lubricants. This kind of oxide film is suitable for engine cylinders or other wear-resistant parts. The membrane has strong micro-pore adsorption capacity and can be colored into various beautiful and gorgeous colors.

(6) Titanium zinc plate

Titanium-zinc plate is made by melting high-purity metal zinc (99.995%) meeting the European quality standard EN1179 with a small amount of titanium and copper. The content of titanium is 0.06%-0.20%, which can improve the creep resistance of the alloy and the content of copper is 0.08%-1.00%, which will increase the hardness of the alloy. Zinc is an excellent and durable metal material with natural corrosion resistance. A dense passive layer can be formed on the surface, so that zinc can maintain a very slow corrosion rate.

It has a long service life, and the metal surface has a life span of 80-100 Jahre. And it has perfect natural color, which can be perfectly matched with any other building materials (Kupferplatte, Aluminiumteller, glass, usw.). When it is used in harsh environments such as strong wind and sandy area, uneven rain area and severe smog area, its unique advantages can be best showed.

(7) Stainless steel plate

Stainless steel plates include mirror stainless steel plates, mat stainless steel plates, titanium plates, usw. The durability and wear resistance of stainless steel plates are very good, but too thin plates will bulge, and too thick plates have very high weight and price, so stainless steel curtain walls are not widely used. It only plays a small role in the decoration of the curtain wall.

(8) Copper plate

Due to its excellent corrosion resistance, copper is very suitable for use as building exterior and roof panels. In Europe, the application of copper on the roofs of superstructures such as churches has a long history, and the copper plate domes of many ancient buildings are still in good use today.

Copper has many valuable physical and chemical properties. It has high thermal conductivity and electrical conductivity, strong chemical stability, high tensile strength, good plasticity and ductility, easy welding, und Korrosionsbeständigkeit.

2. Advantages of metal curtain wall

- Metal is a lightweight material, which reduces the load on the building structure and foundation, and provides a good choice for the exterior decoration of high-rise buildings.

- The metal plate has excellent fire resistance, Wärmeisolierung, Schallschutz, waterproof, anti-fouling and anti-corrosion performance.

- Processing, transportation, Installation, cleaning or other construction operations are easy to implement.

- All of its properties, including excellent processing performance, color diversity and ensured safety, can be designed into various complex shapes, and can process various types of curved lines, give architects a huge space to design and provides more ideas to curtain wall designers

- Metal design adaptability is strong. According to different appearance requirements, performance requirements and functional requirements, various types of decorative effects of metal curtain walls can be designed.

- It is cost-effective with low maintenance cost and long service life.

Notice:

- The anti-deformation ability of curtain wall system must be scientifically calculated for every important part of curtain wall system. Must consider the influence of wind pressure, self-weight, earthquake and temperature on the curtain wall system, and carefully check the embedded parts, connection system, keel system, panels and fasteners to ensure the safety of the curtain wall.

- The floating connection of plates ensures the resilience of the curtain wall after deformation and the integrity of the curtain wall and also ensures that the curtain wall will not be deformed due to force, and avoids the bulge or depression of the curtain wall surface.

- For curtain wall projects, if the panels are in peculiar shapes, the lead time is relatively long as these panels are much more difficult to produce

Auf der Suche nach einem Fassadenlieferanten für Ihre Projekte?

Alumideas ist ein Hersteller von Aluminiumfassaden in China. Wir bieten eine Komplettlösung für Ihre dekorativen Verkleidungsprojekte im Innen- und Außenbereich. Fordern Sie jetzt ein Angebot an!

Wir werden Sie innerhalb von 24 Stunden kontaktieren 1 Arbeitstag, Bitte achten Sie auf die E-Mail mit dem Suffix „@www.alumideas.com“.