Alumideas boasts a team of seasoned and certified engineers, designers, sales consultants, and production experts, deeply committed to the research and development of cutting-edge aluminum wall-cladding solutions. Here’s the project processing for architectural designer. Equipped with state-of-the-art machinery and tools, we are adept at performing sophisticated tests, production, and delivery processes. Ultimately, our mission is to transform your architectural visions into tangible masterpieces.

Dive deep into a comprehensive evaluation of the architectural design you’re considering, focusing on the design and the overall structure of the aluminum panels.

Width: Aluminum panel manufacturers typically use rolled materials with common widths ranging from 1.5m to 2.4m or wider. It’s recommended to prioritize widths of 1.5m or less due to cost-effectiveness and shorter supply cycles. Wider panels can be more expensive and prone to deformation.

Length: Given that most bending equipment can handle up to 6m, it’s not advisable to process aluminum panels longer than this.

Enclosed Cavity Aluminum panels:These can deform or even explode during welding and coating due to heat. It’s best to avoid this design, or if necessary, create ventilation holes in inconspicuous areas.

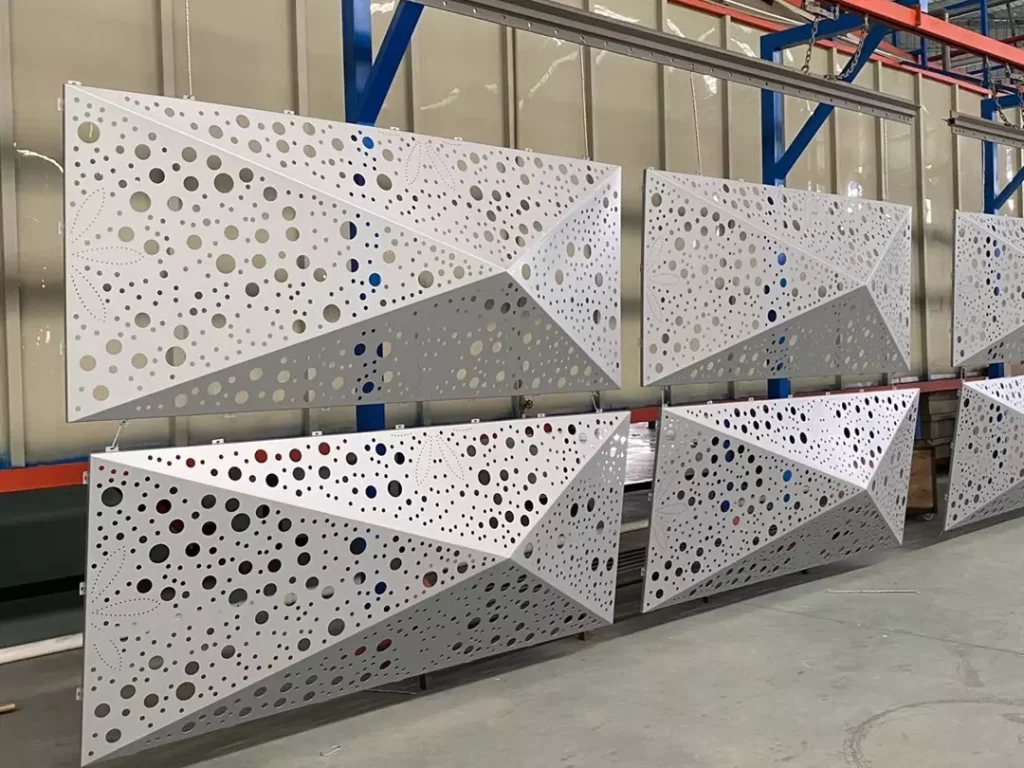

We understand the effort designers put into aluminum panel projects. Our engineers aim to retain the original design concept while suggesting modifications for production feasibility. For intricate designs, we use laser engraving for sharp details, 3D modeling for multidimensional appeal, and curved or double-curved techniques for added depth.

Techniques for Intricate Designs

For designs that demand intricate detailing and unique aesthetics, we employ a range of advanced techniques:

Color Selection:

Our team provides installation advice based on the actual site conditions and ensures feasibility. Each panel is labeled for easy reference and installation.

Our commitment ensures that projects not only adhere to the highest quality standards but are also delivered within the stipulated timeframe, ensuring seamless project progression and client satisfaction.

No matter what style of aluminum panels you want, we can manufacture it according to our rich experience.

In particular, our equipment supports special craftsmanship, which makes the final products more diverse than most aluminum panels on the market.

We help you deliver quality and valuable aluminum panels for your projects, on time and on budget.

Quick Info Exchange Helps Us Serve You Better

Your inquiry will be highly valued and answered by a specialized team.

We will contact you within 1 working day, please pay attention to the email with the suffix “@alumideas.com”.