What is the difference between ACP and ACM?

ACP typically refers to a panel with two aluminum sheets bonded to a polyethylene core, while ACM is often described as a broader term that

Aluminum honeycomb panel is a new type of environmentally friendly decorative material. Compared with other curtain wall materials, aluminum honeycomb panels have better thermal insulation and sound insulation performance.

Certifications

ISO 9001:2015 | SGS certificated | Critical to Quality Inspections

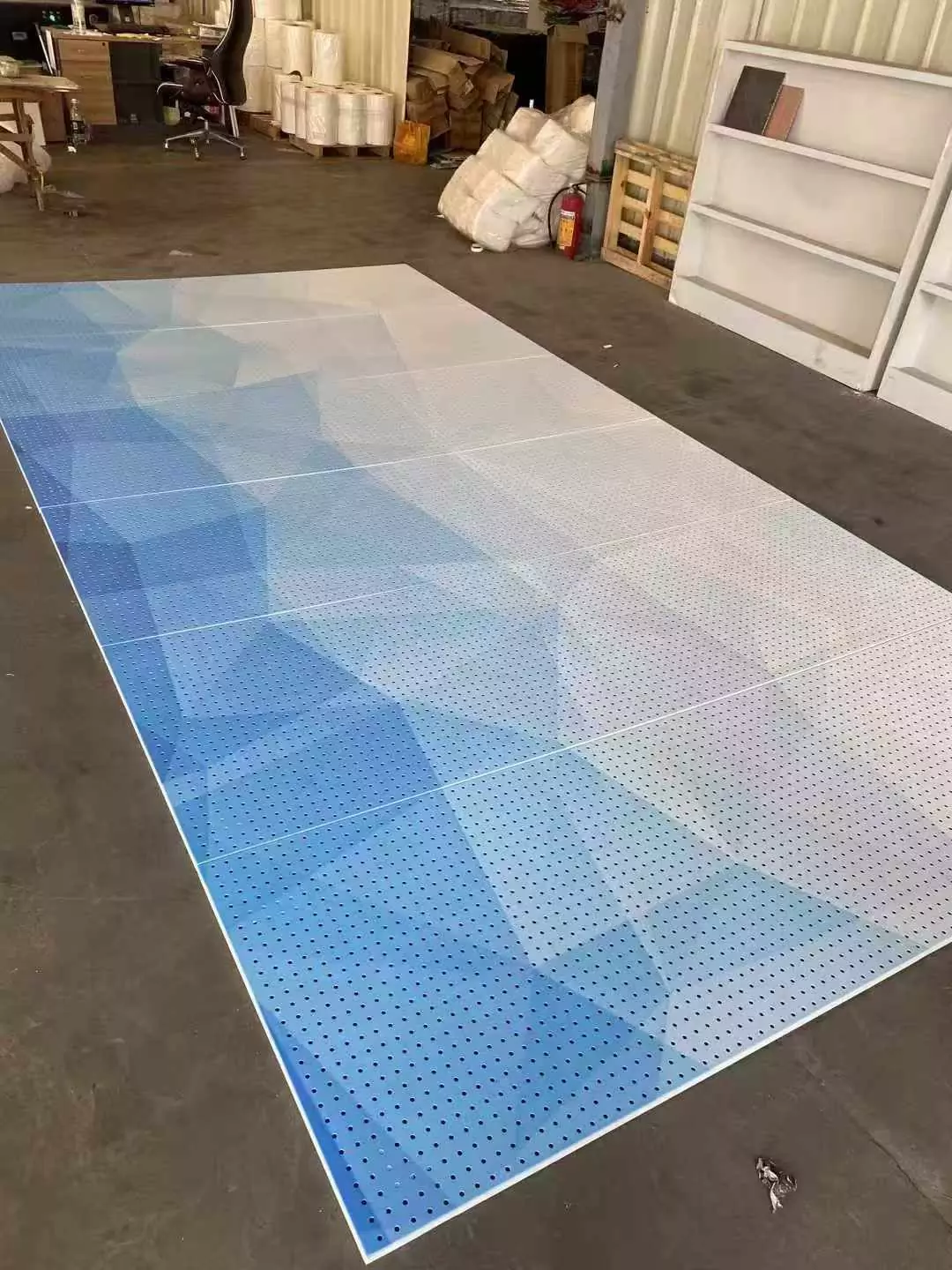

The coating used on the surface of the aluminum honeycomb panel of the curtain wall is a one-time pre-rolled PVDF coating, which can effectively control the color difference and flatness of the surface paint of the aluminum plate, and successfully eliminate the problem of coarse particles in the traditional spraying process, and the color is uniform, delicate, soft and bright. The main component of PVDF coating contains no less than 70% of fluorocarbon resin of Kynar500 or Hylar5000. It is a kind of durable combined coating with the most stable molecular structure. Products coated with PVDF coating can resist ultraviolet radiation in sunlight for a long time, industrial waste gas, Acid rain and chemical erosion can keep the color stable and smooth for a long time, and the coating does not peel, crack, or chalk.

Aluminum honeycomb wall cladding

Honeycomb panel curtain wall

Honeycomb column wrapped

Imitation stone honeycomb panel

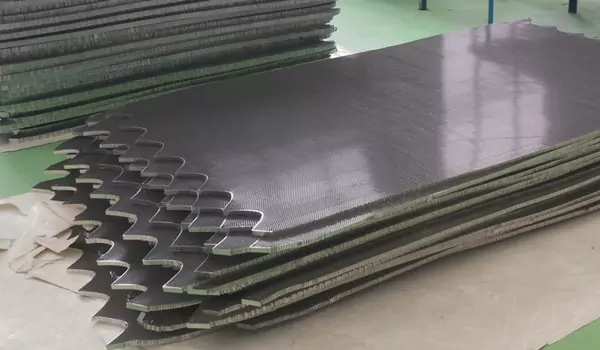

Aluminum honeycomb panels are easy to disassemble and assemble without damaging the panels.Because of its light weight and convenient transportation, it can be transported to different places for multiple reuse

Aluminum honeycomb panels are coated with epoxy-fluorocarbon and have strong corrosion resistance.Salt spray 48 hours without pinhole, crack, no corrosion.

Aluminum honeycomb curtain wall panel can effectively solve the noise problem of aluminum veneer and aluminum plastic board in rainy weather, and the noise can reach 20-30dB for 100-3200Hz sound source.

The thermal conductivity is only 0.0424 / m.K, energy absorption capacity is 150-3500kJ/M,It is a very great thermal insulation material.

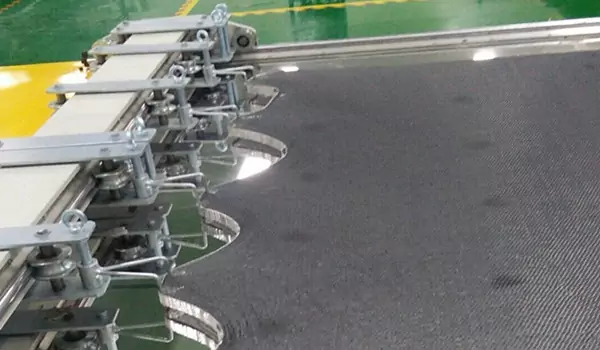

1. Spread out the aluminum honeycomb in advance and cold-press to level it. Duration: more than 4 hours, pressure: 10-25 tons.

2. Prepare glue: the mixing ratio of the main agent and curing agent is: main agent 4, curing agent 1.

3. Raise the press to a suitable height and hang the safety bolt.

4. Lay the bottom plate on the gluing workbench for uniform gluing. (The table should be kept as clean as possible during the process. If there is glue attached to the decorative surface of the aluminum plate, wipe it up in time.)

5. Place the glued aluminum plate in the center on the press table, or on the special cold-pressed mobile tray.

6. Place the spread-open aluminum honeycomb on top of the glued aluminum plate and place it in the center. Ensure that the aluminum honeycomb is bigger than the aluminum plate as much as possible.

7. Repeat the 5 steps for the panel, and then flip it over the aluminum honeycomb.

8. Repeat steps 4, 5, 6, and 7 in a loop, and try to ensure that the aluminum plates are aligned perpendicular to the ground during the stacking process.

9. Cold pressing: try not to exceed 40 honeycomb panels per cold pressing. Cold pressing time: 4-5 hours (room temperature above 15 degrees), 6-8 hours (room temperature below 15 degrees), pressure: 15-25 tons.

To save you time, we have also prepared PDF versions of all product catalogs, only leave your email and you will get the download link immediately.

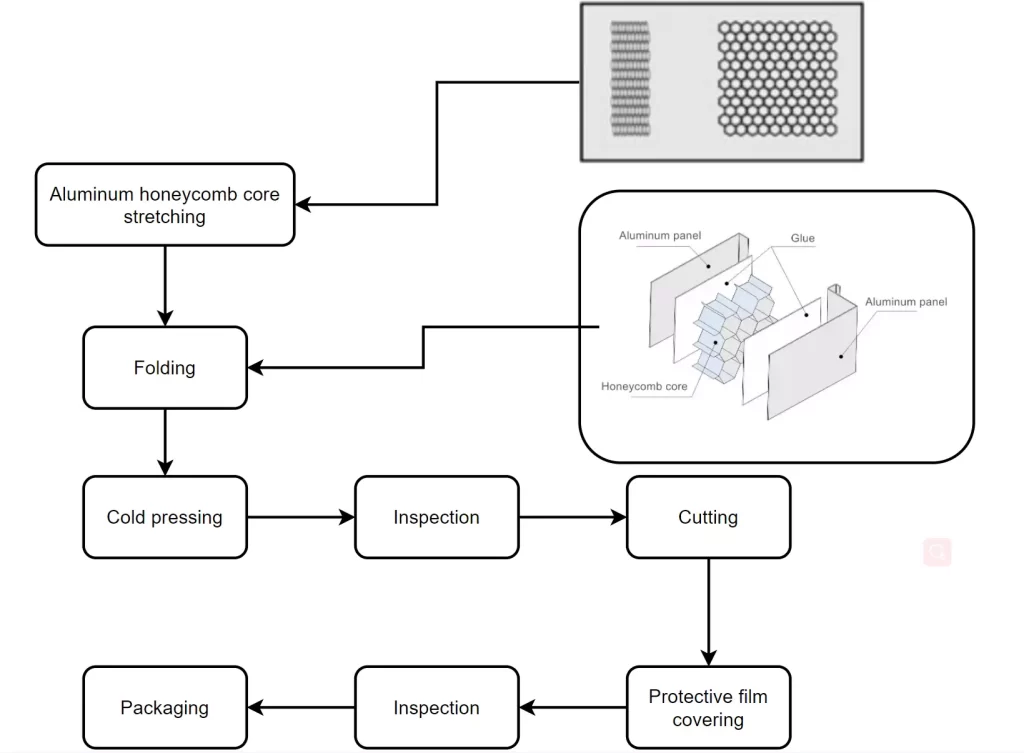

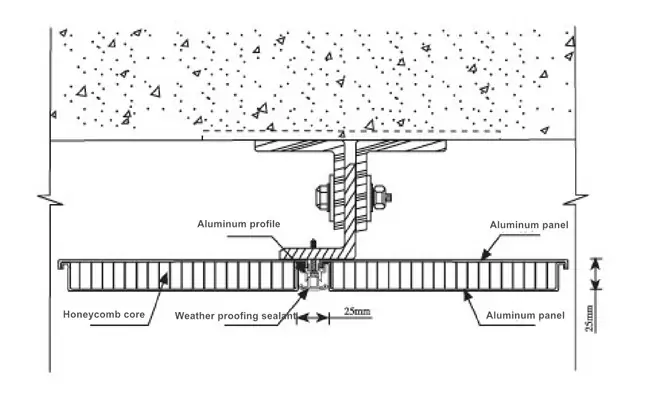

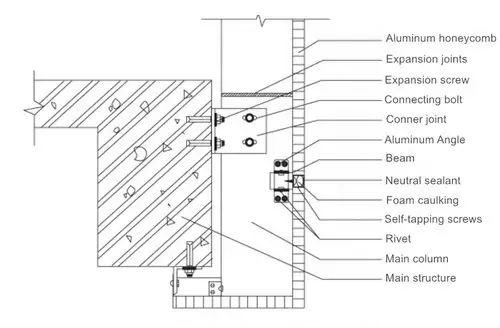

Aluminum panels: Mainly selected high quality 3003H24 alloy aluminum sheet or 5052AH14 high manganese alloy aluminum sheet as the base material, fluorocarboin rolll-coated sheet with thickiness of the 0.7-1.5mm.

Aluminum Sheet: Base sheet thickness is 0.5-1.0mm

Aluminum honeycomb: Honeycomb core material using hexagonal 3003H18 type aluminum honeycamb core, with aluminum foil thickness is 0.04-0.07, edge length is 5-6mm.

Adhesive: Two-component of polymer epoxy film and two-component of modified epoxy resin.

In order to prove that aluminum plastic plate used for curtain wall is reliable and safe, it is necessary to carry out a large number of tests on the coating thickness of aluminum composite panel, penetration resistance,cut strength and the ability to bear wind load. Alumideas has been extensively tested and passed by these projects.

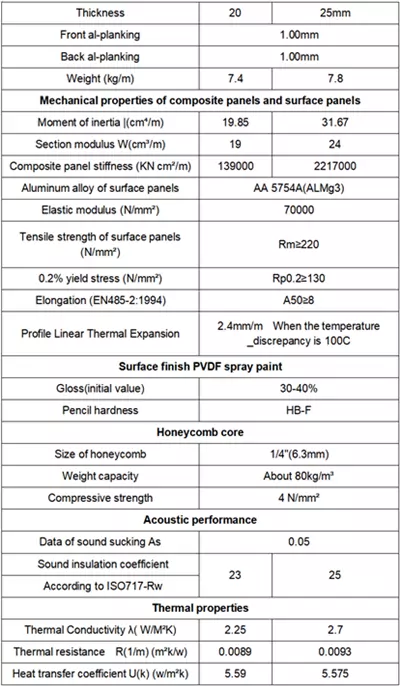

| Thickness | 20 | 25mm | |||

| Front al-planking | 1.00mm | ||||

| Back al-planking | 1.00mm | ||||

| Weight (kg/m) | 7.4 | 7.8 | |||

| Mechanical properties of composite panels and surface panels | |||||

| Moment of inertia |(cm⁴/m) | 19.85 | 31.67 | |||

| Section modulus W(cm³/m) | 19 | 24 | |||

| Composite panel stiffness (KN cm²/m) | 139000 | 2217000 | |||

| Aluminum alloy of surface panels | AA 5754A(ALMg3) | ||||

| Elastic modulus (N/mm²) | 70000 | ||||

| Tensile strength of surface panels (N/mm²) | Rm≥220 | ||||

| 0.2% yield stress (N/mm²) | Rp0.2≥130 | ||||

| Elongation (EN485-2:1994) | A50≥8 | ||||

| Profile Linear Thermal Expansion | 2.4mm/m When the temperature _discrepancy is 100C | ||||

| Surface finish PVDF spray paint | |||||

| Gloss(initial value) | 30-40% | ||||

| Pencil hardness | HB-F | ||||

| Honeycomb core | |||||

| Size of honeycomb | 1/4″(6.3mm) | ||||

| Weight capacity | About 80kg/m³ | ||||

| Compressive strength | 4 N/mm² | ||||

| Acoustic performance | |||||

| Data of sound sucking As | 0.05 | ||||

| Sound insulation coefficient According to ISO717-Rw | 23 | 25 | |||

| Thermal properties | |||||

| Thermal Conductivity λ( W/M²K) | 2.25 | 2.7 | |||

| Thermal resistance R(1/m) (m²k/w) | 0.0089 | 0.0093 | |||

| Heat transfer coefficient U(k) (w/m²k) | 5.59 | 5.575 | |||

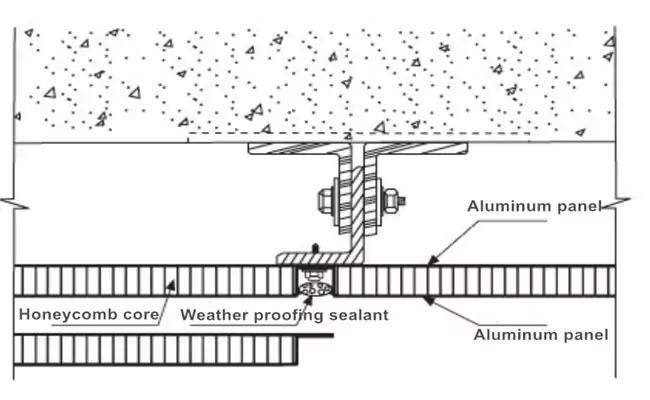

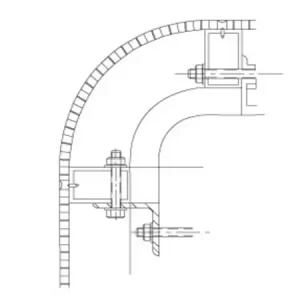

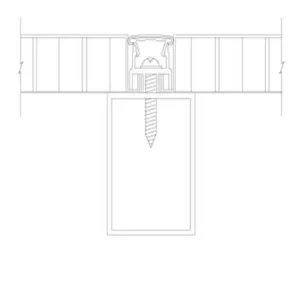

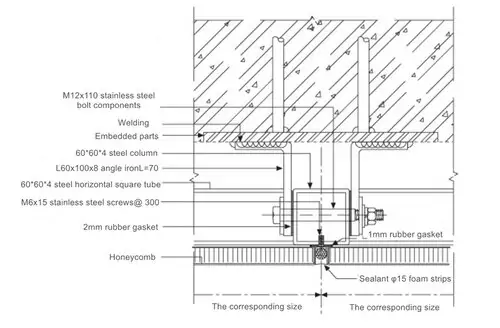

Alumideas honeycomb panel has high strength and rigidity and lightweight, and beautiful visual decorative and long service life, so the application is extensive, such as curtain wall, car, hull, especially on the building, can withstand high wind pressure and extreme weather, meet the requirement of most of the architectural design, and also has the excellent smoothness. Common installation ways are as below:

Shorten your product development cycle by weeks (and sometimes months) and produce panel sample and finish qualification tests within days. Some aluminum veneer samples can be shipped within 3 days.

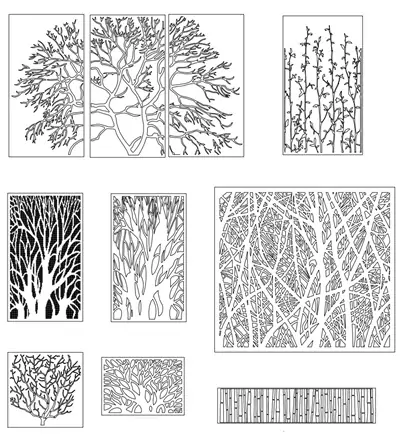

Each quote includes real-time pricing and design analysis.We evaluate your 3D CAD and help identify any features that may be challenging during the manufacturing process, such as multifaceted folding of special-shaped plates and high precision engraving.In addition, our team of experienced application engineers can discuss your unique design, evaluate cost trade-offs, and even help you optimize aluminum sheet drawings and make design changes through our consulting design services.

We have complete automatic spraying equipment line, temperature control furnace, LPG combustion system and German pretreatment technology. The surface is made of high-quality PVDF coating from PPG, DNT, AKZO, NIPPON and other world-famous PVDF coating manufacturers, with a wide range of colors and can be customized in any color with your color sample

Alumideas has over 60+ oversea project in more than 30 countries for more than 10 years. Familiar with aluminum wall cladding design and installation methods in different countries and able to give professional advice, so as to promote customer’s engineering projects

Alumideas is a aluminum honeycomb panels manufacturer in China. We provide a one-stop solution for your interior and exterior decorative cladding projects. Ask for a quote now!

We will contact you within 1 working day, please pay attention to the email with the suffix “@www.alumideas.com”.

You come with your aluminum panel project, our staff greet you with their smile and most importantly, their knowledge.

They can help you in these ways:

In the project, aluminum plates (panels)need to be perfectly connected with other materials of the building. However, as the general engineering drawings involve too many materials, it is impossible to mark the installation and other information of each material in great detail, and the characteristics of each material are only be known by the corresponding supplier, so it is necessary for technicians to optimize the drawings.

The technicians will help in these ways:

Under EXW term, customer need to arrange freight transportation themselves; Under INCOTERMS such as FOB, C&F and CIF, logistics forwarder will be needed to take charge of all kinds of documents and deal with customs.

Our experienced logistics forwarders will help you in these ways:

After you communicate and get what you want to know from our staff, our professional sale will come to you and follow up your project.

He/She will help you in these ways:

Alumideas manufactures all aluminum panels in our own facilities, which are eco-friendly buildings. Alumideas highly takes environment protection in all working areas into consideration by decreasing waste in all production processes.

Accepting OEM and ODM, Alumideas will help you in these ways(based on the process of manufacturing):

The transaction does not end when the customer receives the goods; it’s just the beginning. Our sales will follow up the situation of products including their quality, quantity. And further, they will help to make plans for the sales of goods.

We promise to provide every customer with satisfactory aluminum plates and services. We also know that you may encounter an problem and need assistance. Friendly and courteous customer service experts will always be ready to provide timely solutions.

ACP typically refers to a panel with two aluminum sheets bonded to a polyethylene core, while ACM is often described as a broader term that

Some customers might not have adequate knowledge on the support frame for the aluminum facade panel. That’s why we write this article. Aluminum facade panels

Now, the application of UV printing design of aluminum plates is becoming more and more widespread It has the advantages of structural design and space

Your inquiry will be highly valued and answered by a specialized team.

We will contact you within 1 working day, please pay attention to the email with the suffix “@alumideas.com”.

Quick Info Exchange Helps Us Serve You Better